Periodic

Performed annually

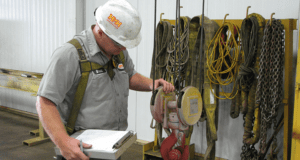

In periodic inspections, Harriman will inspect your lifting units in accordance with:

- OSHA Regulations 1910.179, Overhead and Gantry Cranes.

- Appropriate ANSI/ASME Standards for Overhead and Gantry Cranes and Hoists.

Our service technicians will check the hoisting and traveling drives, the general condition of the runway rails, electrification and controls. They will test the equipment, inspect all mechanical and electrical parts that are visible, and identify any items that need replacement. At the completion of the service, one of our service technicians will discuss the results of the inspection with the appropriate representatives of your organization. In addition, you will be provided with a written report for each lifting system.

Specifically, our technicians will:

- Inspect and test the hoists, trolleys, and cranes for proper operation.

- Inspect the motor brakes for proper operation.

- Visually examine the sheaves, drums, wheels, and bearings.

- Visually examine the hoist cable or chain for kinking, crushing, cutting, or corrosion.

- Insure that the hoist reeving is correct.

- Inspect the end stops, bumpers, and rail sweeps.

- Inspect the collector shoes, brushes, and wheels for signs of arcing and wear.

- Inspect the external motor couplings and wiring for wear and deterioration.

- Visually check the electrical control enclosures for broken or loose connections and proper operation.

- Check the hoist, trolley, and crane control units for proper operation.

- Examine the hooks for wear, bends, and cracks. Insure that the safety devices are not missing.

- Inspect and test the safety devices such as lights, horn, and limit switches.