Services

Runway Surveys

Crane runways are at the foundation of good crane health. Runways are originally installed to be within the tolerances published in CMAA recommendations. These tolerances are in many cases plus or minus 1/8 of an inch in span and within ¼ inch of each other in elevation. No mater what type of overhead crane system you have in your plant, good runway systems are the key to safety and reduced maintenance.

Laser Runway Surveys and Runway Inspections

Harriman is experienced in the area of performing crane and hoist inspection surveys that include: runway girder elevation, runway rail straightness and span compliance. In addition to those items Harriman also checks the general condition of the running surfaces.

Reporting

Out team of professionals perform necessary field measurements and inspections and relay them back to our drafting department for them to produce drawings. These drawings will illustrate the condition of your existing crane runways as well as demonstrating how much if any of the runways is out of allowable tolerance. As part of our reporting a written report with images illustrating non compliance issues will be provided.

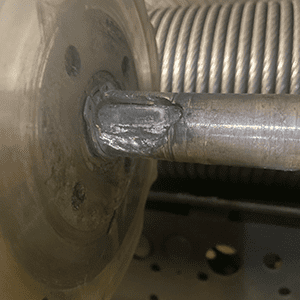

Bridge Structural Analysis

Bridge girder and end-truck connections can be inspected both visually and by using a non-destructive means of testing these areas. Our Structural Analysis Inspectors are trained to identify cracks in and the yielding of materials in the areas of these connections.

During a structural analysis inspection, we perform a squareness check of the cranes wheels and a laser check to determine that the bridge crane has the proper camber.