WIRE ROPE HOISTS

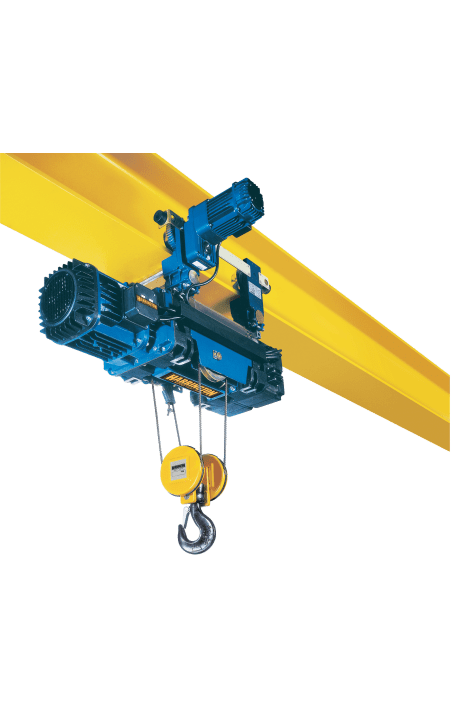

RTY Wire Rope Trolley Hoists

Designed for Safety, Reliability and Performance

Our ultra-low headroom trolley hoists have an H4 duty rating for high demand applications and come standard with VFD controls for ultimate lifting and lowering accuracy.

CAPACITY

- 3-10 Ton

COMPLIANCE

- NFPA 70 “National Electric Code”

- ASME B30.16, “Safety Standard – Overhead Hoists (Underhung)”

- ASME HST-4, “Performance Standard for Overhead Electric Wire Rope Hoists”

- RY hoists in standard configurations (including certain options) are certified to UL 1340 “Standard for Hoist”, CSA 22.2 No. 33

ROPE SYSTEM

- Premium Wire Rope (IWRC coated core)

- Full 360 ̊ rope guide

- Deep grooved rope drum

VFD (Variable Frequency Drive)

- Soft start/stop minimizes load swing

- High and low speed adjustability

- Maximum speed ratio of 6:1

- No-load high speed function

STANDARD VOLTAGE

- (208-230)-3-50/60

- 460-3-50/60

CONTROL VOLTAGE

- 110V

BRAKE

- Pull-rotor motor brake 3 & 5 Ton; Magnetic disc brake 7.5 & 10 Ton

- 5-year warranty

MOTOR

- Totally enclosed fan cooled (TEFC)

- Class F insulation and ribbed frame for maximum cooling and durability

- IP55 rating

OVERLOAD PROTECTION

- Electronic overload limiter

OPERATING CONDITIONS

- Recommended for -4 ̊ to +104 ̊ F and humidity of 90% or less

OPTIONS

- Pendant

- Power supply cord

- Flange extension kit

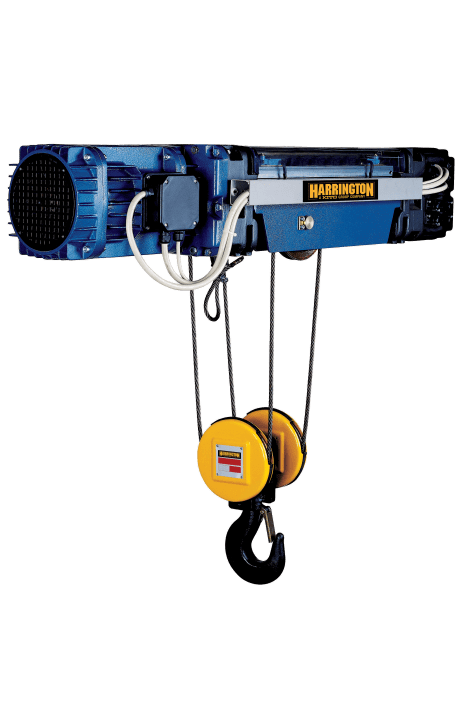

RH Wire Rope Trolley Hoists

Superior Load Positioning

For general use on bridge, gantry or jib cranes, as well as monorails, this standard headroom Harrington monorail style trolley hoist combines versatility and performance.

CAPACITY

- 2 – 20 Ton

STANDARDS

- NFPA 70 “National Electric Code”

- ASME B30.16, “Safety Standard – Overhead Hoists (Underhung)”

- ASME HST-4, “Performance Standard for Overhead Electric Wire Rope Hoists”

BODY

- Standard headroom configuration

ROPE SYSTEM

- Premium grade provides high resistance to fatigue and wear

- Spring-tensioned rope guide keeps the rope securely in the grooves on the drum

HOOK

- High strength forged steel

- Capable of swiveling 360 degrees under load

- Top and bottom hooks have heavy-duty hook latch

- Machined carbon steel bottom block sheaves

OPERATION

- Triple reduction helical gearing for smooth, quiet operation with minimum vibration

- Electro-Mechanical load limiter prevents lifting of over capacity loads

- External limit switches protect against hook overtravel

BRAKE

- Conical rotor brake virtually eliminates brake issues

- Fan cooled to ensure long life

MOTOR

- Hoist and trolley feature a heavy-duty fan cooled (TEFC) motor

- Class F insulation

- Includes thermal protection

- Finned cast aluminum housing for maximum durability

RUBBER BUMPERS

- Reduce mechanical impact against trolley stops and are required for trolley hoist installation on overhead bridge cranes

DUAL TREAD WHEELS WITH GEAR GUARDS

- Flat and tapered tread section is ideal for S or W beams

- Ensures smooth tracking on wide flange beams common in industry

- Gear guards protect gear ring and flange, as well as personnel

EXTENDED WHEELBASE DESIGN

- Larger wheelbase than competitive units offers more stable travel

- Provides better load distribution over the beam to reduce beam loading

DUAL-SIDE TROLLEY DRIVE

- Two driven wheels offer better traction for improved operator control

- Driven wheels on opposite sides of the trolley provide smoother operation with less racking and skewing

HEAVY-DUTY TROLLEY DRIVE

- Fan-cooled TEFC drive motor provides long, trouble-free service

- IP55-rated, suitable for outdoor service and adds extra protection for indoor applications

- Helical gear drives in oil bath provides cool, quiet and smooth operation

- Trolley motor design provides smooth acceleration

OPTIONS

- Pendant

- Pendant cord

- Power supply cord

- Trolley travel limit switch

- Block operated limit switch

RH Wire Rope Hoists

Deck/Base Mounted or Lug Suspended Solution

Harrington RH wire rope hoists are designed and built for today’s heavy-duty wire rope hoist applications including fabricating, die handling, paper mill and production line work. State-of-the-art design features and construction make the RH extremely durable, highly reliable and very low maintenance for years of trouble free service.

CAPACITY

- 2 – 20 Tons

COMPLIANCE

- NFPA 70 “National Electric Code”

- ASME B30.16, “Safety Standard – Overhead Hoists (Underhung)”

- ASME HST-4, “Performance Standard for Overhead Electric Wire Rope Hoists”

BODY

- Modular for all mounting configurations with the hoist oriented parallel to the beam

- Single axis in-line design

ROPE SYSTEM

- Premium grade provides high resistance to fatigue and wear

- Spring-tensioned rope guide keeps the rope securely in the grooves on the drum

HOOK

- High strength forged steel

- Capable of swiveling 360 degrees under load

- Top and bottom hooks have heavy-duty hook latch

- Machined carbon steel bottom block sheaves

OPERATION

- Triple reduction helical gearing for smooth, quiet operation with minimum vibration

- Electro-mechanical load limiter prevents lifting of over capacity loads

- External limit switches protect against hook overtravel

BRAKE

- Conical rotor brake

- Fan cooled to ensure long life

MOTOR

- Heavy-duty fan cooled (TEFC)

- Class F insulation

- Includes thermal protection

- Finned cast aluminum housing

OPTIONS

- Pendant

- Pendant cord

- Power supply cord